- Home Page

- Company Profile

-

Technologies

- Oilseed Preparatory Plants

- Oilseed Extraction Plants

- Crude Oil Filtration Plants

- Edible Oil Refining Plant

- Soya Lecithin Plants

- Conveying Systems

- Plant Heat Exchanger

- Solvent Extraction Plant

- Expander Machine

- Seed Cleaning Machinery

- Distillation Plant

- Bucket Elevators

- Fractionation Plant

- Dewaxing Plant

- Edible Oil Plant

- Cooing Tower

- Mechanical Extraction Plant

- Scrapped Ssurface Heat Exchanger

- Conveying Equipment

- Downloads

- Contact Us

Quality Assurance

As a quality conscious organization, we always focus on manufacturing and offering superior quality Industrial Plant Machinery and Associated Equipment.

Infrastructural Set Up

We have established state-of-the-art infrastructural set-up, which enables us to offer precision engineered range of Industrial Plant Machinery and Associated Equipment within minimum lead time.

Our Team

With the support of our team, we have acquired domain expertise. Our team of experts is highly qualified and has in-depth knowledge about the industry so as to offer qualitative assortment to the clients.

Client Satisfaction

We are delivering quality range of Industrial Plant Machinery and Associated Equipment to the clients in order to gain their utmost satisfaction.Dealing in a wide range of industrial plant & machinery such as thermic fluid boiler, lecithin plant, surface heat exchanger, industrial heat exchanger, etc....

Welcome To V Tech Engineering!

About Us:

V Tech Engineering was previously acknowledged as Shri Yash Fabricators And Consultancy. It started the journey a decade ago in Madhya Pradesh, India. Our company is engaged in manufacturing machines and plants while offering turnkey solutions to the industry of Edible Oil. The projects delivered includes lecithin plant, edible oil refinery, mechanical extraction plant, solvent extraction plant, etc. Inferable to our accurate engineered range, client-centric approaches, and well-facilitated manufacturing unit, our company has been to create a massive client base across the Indian and global markets within a short period. Our equipment range is highly acclaimed by the customers for robust construction, high efficiency, and low maintenance. Being a quality centric company, we focus on delivering quality and hi-tech equipment to the customers. Therefore, our comprehensive collection of equipment undergoes vigorous quality testing at regular interims by the qualified and trained quality analysists. moreover, our well-equipped infrastructure helps us to fulfil the bulk orders of our clients inside the set time frame. While exporting the equipment collection to more than fifteen countries, our company has attained global recognition by expanding itself every year. In short, our company is emerging as among the finest technology and Machinery provider and Manufacturer for the industry of edible oil. Why Prefer Us?- Alteration and modification

- Capabilities and strength

- Commissioning

- Engineering consultancy

- Installation

- Manufacturing facility

- Tailored made fabrication

- Technical evaluation

- Turnkey solution

Let's Talk Business!

Please take a quick moment to complete this form and a business representative will get back to you swiftly

GET A QUOTE

Request a Quote

Products Gallery

-

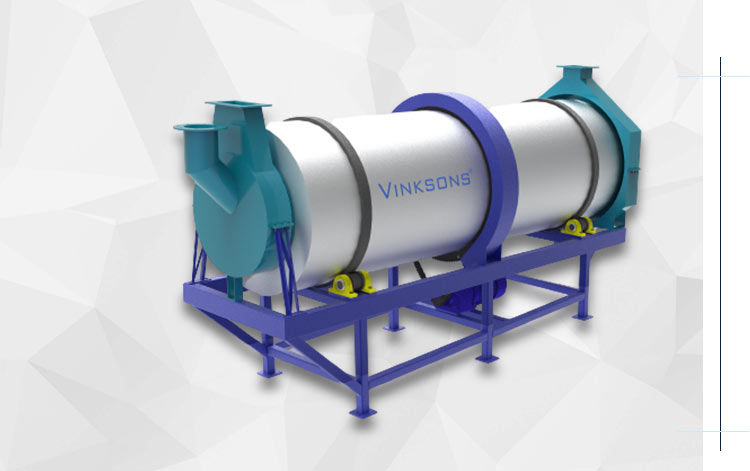

Dryer Cooler -

oilSeed Preparatory Plant -

Cooker Conditioner -

Desolventiser Toaster -

Plate and Frame Filter -

Membrane Filter -

Pressure Leaf Filter -

EDIBLE OIL REFINERY -

Pre Treatment and Bleaching Plant -

Edible oil Deguming Plant -

Lecithin Plants -

LECITHIN PLANT -

Conveying System -

Bulk Flow Conveyor -

Tube Conveyor -

Shell and Tube Heat Exchangers -

Double Pipe Heat Exchanger -

Scrapped Surface Heat Exchangers -

Solvent Extraction Plant -

Solvent Extraction Machinery -

SOLVENT EXTRACTION PLANT -

Expander Machine -

Seed Cleaning Machinery -

Edible oil Distillation Plants -

Bucket Elevators -

Rbd Palm Fractionation Plant -

Dewaxing Plant -

EDIBLE OIL PLANT -

COOLING TOWER -

MECHANICAL EXTRACTION PLANT -

SCRAPPED SURFACE HEAT EXCHANGER -

CONVEYING EQUIPMENT

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese